My neighbor put a working Heathkit oscilloscope out in his trash. Naturally, I rescued it. Time to make another clock!

My neighbor put a working Heathkit oscilloscope out in his trash. Naturally, I rescued it. Time to make another clock!

Acquisition

Trash day is a wonderful time in my neighborhood. I once saved a working Mac Classic from the local sanitation engineers, and I’ve found computers that I harvested for parts in my mini Altair 8800 PC. But my best find was just last month, when I scored a vintage oscilloscope! And it was a Heathkit!! And it works!!!

The scope I found was sold in the early 1960s. It uses vacuum tubes and its maximum sweep rate is 100 kilocycles (this was before Hertz was invented) – very slow by today’s standards. What should I do with it? I could use it as an oscilloscope, of course (for some reason, using an oscilloscope as old as I am doesn’t seem as bad as using a computer as old as I am). But the sad truth is, this scope was only minimally useful even when it was new. It can show you the shape of an electrical signal, but it can’t tell you the magnitude (i.e. how many volts) or the timing (e.g. are you viewing something that happened in 1/200th of a second or 1/1000th of a second?). It’s not worth much either; similar scopes fetch less than $50 on eBay.

I decided to turn my oscilloscope into a clock. God knows, I don’t need another clock, but what else can I do? Along the way, I smoked some components and, in keeping with my love for deadly projects, almost electrocuted myself.

Transformation

A fellow named Jan de Rie made a board that connects to an oscilloscope and displays an analog clock on the scope’s screen. Johannes’ board is now sold by Sparkfun. I bought one, and it worked fine with my old piece of garbage.

Well, not quite. The clock was flipped horizontally. My first thought was to swap the signal and ground on the horizontal input. That didn’t work: the scope internally connects the grounds from the horizontal and vertical inputs. Swapping the horizontal’s signal and ground just resulted in shorting the vertical signal to the common ground.

Being a software engineer, my next thought was to modify the open source code for the clock board to flip the image horizontally. But up until now, I’ve been working with PIC microcontrollers, and this board is based on an AVR microcontroller. I would need to download new development tools, figure out how to use them, figure out how to download programs to the AVR, etc. I’m sure I’m capable of it, but software is my day job. Doing all that seemed like work, not play.

I settled with option 3, which was to feed the board’s horizontal signal into an inverting op amp circuit and to map its 0-5 volt range to a 5-0 volt range. The board’s horizontal output was barely enough to fill the scope’s screen, even at the scope’s maximum amplification, so if I lost any of that 5V range (e.g. so it goes from 4V to 1V) the clock display would be too narrow. I also wanted to feed the op amp from the board’s 5V supply, so that I didn’t need a separate power supply. To meet these goals, I would need a rail-to-rail op amp. Radio Shack doesn’t sell ’em, but fortunately, I had some Microchip MCP604s lying around. They’re quad op amps, and I only needed a single, so it was bigger than I needed. But I wasn’t tight for space; I figured I’d use one of the op amps and ground the other three.

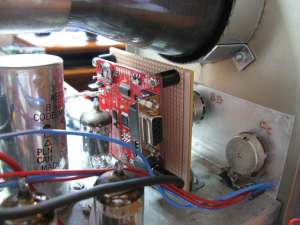

So I built a host board for the clock. The clock board feeds power and its horizontal signal to the host board which inverts it with the op amp.

I wanted to integrate the host and clock boards into my scope, but still preserve its usability as an oscilloscope. There’s enough empty space inside the scope for it. The scope has terminal strips attached underneath the main platform by screws. I could use those same screws with L-brackets on the top of the platform to hold the host board.

The clock board has two buttons on it for setting the time and configuring the display. I needed a way to access them once the board was inside the scope. And I needed a way to switch between normal scope behavior and the clock display.

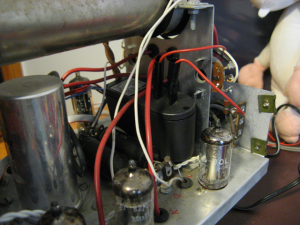

The back panel of the scope already had a slide switch and two banana jacks. The switch selected the signal going to the vertical control of the CRT: either the signal would come from the jacks on the front of the scope (after passing through an amplifier circuit) or it would come from jacks on the back of the scope (without passing through an amplifier).

So for the first time in 30 years, I took a soldering iron to a Heathkit. I removed the rear jacks, drilled the holes a little bigger, and installed two buttons. They got wired to the host board, which was in turn wired to the traces on the clock board for the two switches. I rewired the slide switch so that it selected the source for both the horizontal and vertical inputs: either the jacks on the front of the scope, or the internal clock board.

Burning Smell

I wrestled for a while over how to get power to the board. There’s power available inside the scope of course: 325 volts and 850 volts. No thank you. There’s also a 6.3 volt output from the transformer. The voltage regulator on the clock board needs between 7 and 15 volts DC. I thought I could wire up a voltage doubler to boost 6.3 volts AC to 12.6 volts DC and plug it into the clock board. Here I must confess my incompetence in electronics: I prototyped the voltage doubler, hooked it up to the op amp (thinking I could kill two birds with one stone: if I had 12.6 volts, I could amplify as well as invert the X axis signal and I wouldn’t need a rail-to-rail op amp). The voltage was indeed doubled, but my diodes were getting hot and my op amp smelled of smoke. It turns out that I was pulling over one amp. I still don’t understand why.

So I opted for the easy way out. I have zillions of power adapters lying around, and I found the smallest one that outputs 12V. I soldered it to the 120VAC coming into the scope and plugged the output into the clock board. Everything worked and nothing blew up.

I did, unfortunately, give myself a few electrical shocks along the way. I know about discharging capacitors in high-voltage circuits, but my mistakes were far clumsier than that. One time, I was fiddling near the on/off switch and I had forgotten to unplug the scope. It took a few shocks for me to realize it wasn’t just a mechanical poke by a wire. Another time, I was reaching around from the front to flip the rear switch while the scope was on, and the palm of my hand brushed the back of the CRT. That gave me the unmistakable tingle of AC current. After this project, I’ll be happy to go back to 5 volt digital circuits.

Ultimate Success

The end result is a vintage Heathkit scope with a secret: flip the switch on back and it turns into a clock.

I’d really be impressed if you turned a clock into an oscilloscope, but this is an awesome hack. I’ll have to think about turning my old HP oscilloscope into a clock.

Hi Bob–

Found this post & those at SparkFun to be very helpful for me to get a Heath IO-10 working as a scope clock. I also have an inverted clock, but found if I run a wire from one of the scope ground posts to either Gnd or Zint on the board, my clock faces correctly but is rotated 90 degress to the left. The easiest correction for that is to lay the scope on its side; that orientation resembles the control layout of better scopes and is within my capabilities ;-). Did you ever try the rewiring suggested on the SparkFun forum; I think it involved switching pins 9 and 10? I’m not sure I’m up to the task of your op-amp circuit ;-). Tnx agn.

Hi Paula,

I did not see that Sparkfun post you’re referring to. Can you give me a link to it?

If your clock is rotated 90 degrees, I would think that swapping the vertical and horizontal inputs would set it right. But if it’s still inverted, then you’re back to my (and your) original problem.

Is there anything I could do to help you with an op amp solution? Is it an issue of figuring out the schematic, or soldering a board together?